I sometimes ponder the thought of why the things I do which seem to most, is not logic or in fact turn out the way they do. It seems that the clients I deal with demand the clean unbiased taste without the add-on’s that come or are associated with starter cultures and such, that is to say that they are not needed especially with home curers

I was asked via pm from someone looking for a Chorizo recipe and loved the way mine looked and asked if I would share the recipe, I replied that if they did not mind waiting that I would have time on the weekend. It was also lucky as I had been taking photos for my own records

This then is a recipe that I picked up while working on the ships many years ago while in the Med of an air dried Spanish Chorizo

Boneless pork picnic (shoulder) a bit too lean so need to add some back fat

Spices (clockwise – paprika, Crushed/flaked chillies, Cure 2, Oregano, Salt, Black pepper), Red wine and fresh garlic

Corse ground once

Ready for mixing with spices, red wine and garlic

Completely mixed and ready for second grind

Corse ground the second time

Linked and ready for hanging overnight for drying before going out to the smokehouse for cold smoking

Back from the smokehouse and starting the drying process 12 degrees C @ 68% humidity, my normal space is a 15 degrees C @ 70% humidity

Drying is an art in itself and a fine balance of not drying too fast which incurs the dreaded problem of ‘case hardening’ There are ways to get around this but as with everything it takes time (which for most is a precious commodity) as well as dedication

I was taught by the old timers about the feel of the product one is trying to dry, to check three times a day; two is a must (morning as well as evening) and if the product was drying too fast wipe it/them down with a wet cloth. This was the way the old ones did it in their homes (and is still done this way these days with some).

My friend who taught me the above also showed me how to slow the drying process down which usually prevents the dreaded case of case hardening, what we do is transfer the product to our cooler which (mine) runs at 0 to 1 degrees C

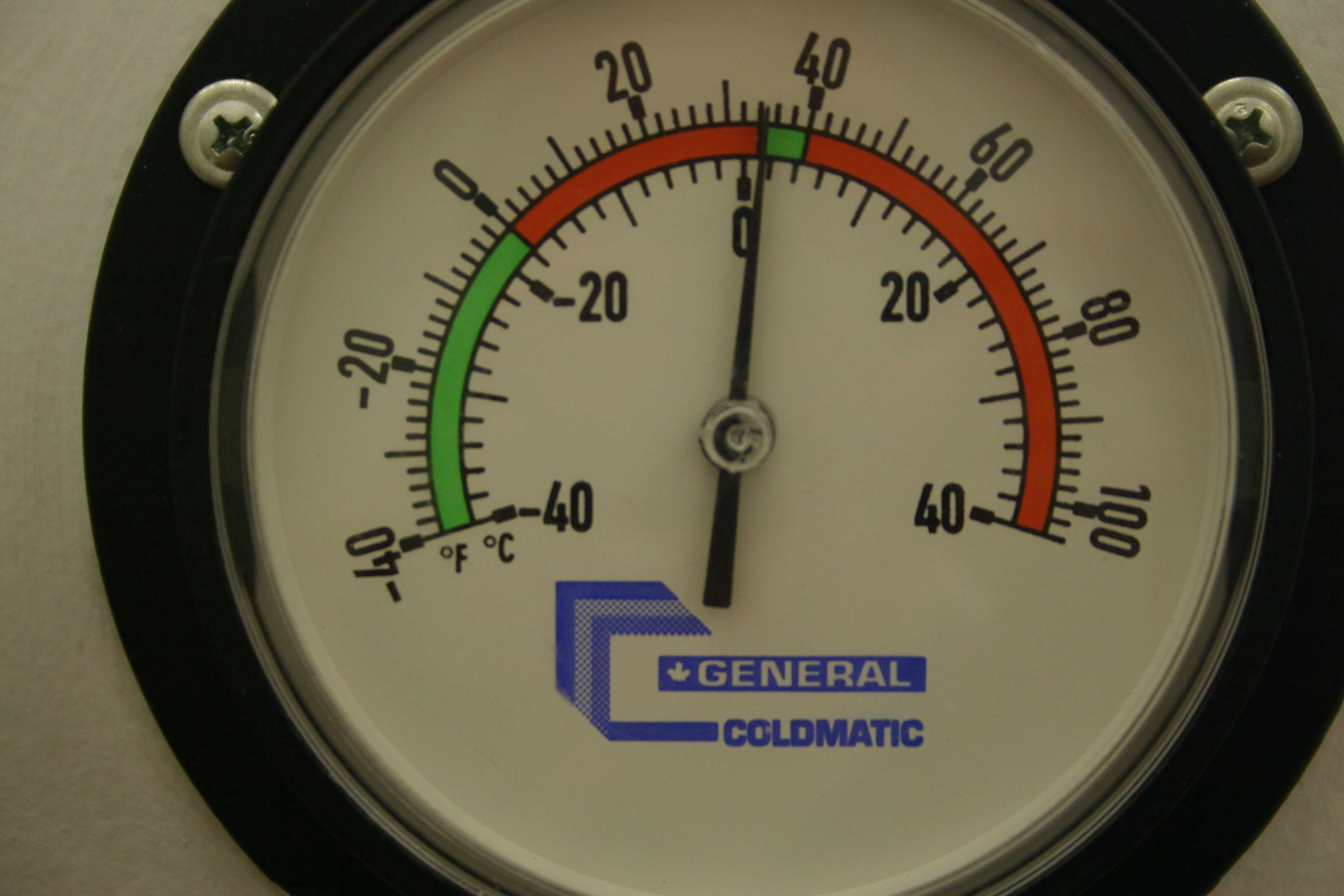

if one looks at the temp/humidly on the inside of the cooler we see something interesting – we have a high humidity which works well with the drying process preventing case hardening

After four days at 12 degrees C @ 68% humidity the casing was firm enough that they needed to be transferred into the cooler where they will stay until they are firm enough to the feel which will mean that they have lost 30%

As for mould ---- we will leave that for another day

I do hope that this has been of some help

Spice per Kg of meat - Pork Shoulder

10g Salt

3.5g Black pepper

13.5g Paprika

5.5g Crushed/flaked Chillies

1.5g Oregano

6g Fresh Garlic

21ml Dry red wine

3g Cure 2

I will post the dried product when ready

Edited 2 times due to missing ingredient & instruction