Dry Cured Ham ...... Irish Ham

49 posts

• Page 3 of 4 • 1, 2, 3, 4

Great Recipe.

Hi BriCan.,

Great Recipe.

My wife is Irish (left when 20) so if you need her expert advice (for free of course) just send us one of them in the post and I will get you any flavour profiling / market research needed...

On another Irish point. My wife still pines for Irish boiling bacon. I've tried legs in Old English, Boston butt in different mixes. I stumbled on a site that says traditional Irish boiling bacon (for Bacon, Cabbage and potatoes) is simply a pork loin cured using a wiltshire cure. Cured for 4 days, left to dry / equilibrate ??? for about 5 day. Boil and serve. I got a loin from the store tonight and have it in the cure. I'll let you know the verdict if you want. Nothing else has come close for her so we'll see.

Again, great to read your posts. Agree with an earlier reply that the pictures on the de-boning were excellent although I'm still not going to try it.

Cheers

Neal

Great Recipe.

My wife is Irish (left when 20) so if you need her expert advice (for free of course) just send us one of them in the post and I will get you any flavour profiling / market research needed...

On another Irish point. My wife still pines for Irish boiling bacon. I've tried legs in Old English, Boston butt in different mixes. I stumbled on a site that says traditional Irish boiling bacon (for Bacon, Cabbage and potatoes) is simply a pork loin cured using a wiltshire cure. Cured for 4 days, left to dry / equilibrate ??? for about 5 day. Boil and serve. I got a loin from the store tonight and have it in the cure. I'll let you know the verdict if you want. Nothing else has come close for her so we'll see.

Again, great to read your posts. Agree with an earlier reply that the pictures on the de-boning were excellent although I'm still not going to try it.

Cheers

Neal

- Nhannath

- Registered Member

- Posts: 26

- Joined: Thu Oct 07, 2010 3:29 am

- Location: Charlotte, NC

Well it’s been some time since I dropped in --- holidays were one thing but what made it special was to meet up with friends from this forum. It seems that I must have enjoyed myself too much or maybe the possibility of drinking out of wet glasses as I came down with the flu bordering on pneumonia.

Had to leave orders for the Irish hams that I placed into the cooked brine at the beginning of May to be cold smoked the week I got back from the UK

The following is the first one cooked off for the client, the aroma of the cold smoke mingled with the spices that was used for the cooked brine in the drying room started to drive some people over the edge.

I will be taking a sample of this on Monday

Had to leave orders for the Irish hams that I placed into the cooked brine at the beginning of May to be cold smoked the week I got back from the UK

The following is the first one cooked off for the client, the aroma of the cold smoke mingled with the spices that was used for the cooked brine in the drying room started to drive some people over the edge.

I will be taking a sample of this on Monday

But what do I know

-

BriCan - Registered Member

- Posts: 2203

- Joined: Wed Apr 07, 2010 12:07 am

- Location: West Coast of Canada

-

vagreys - Site Admin

- Posts: 1653

- Joined: Sun Oct 29, 2006 3:54 pm

- Location: North Chesterfield VA USA

vagreys wrote:Shove some through the interwebs, would ya?

Nice to see you back, hope the girls are settled and that you had a good visit with family, I am assuming you did not get the brown envelope which was sent the day after I left

Phil has his cuz I more or less hand delivered it

Will send off a centre cut (ov thu am that iz) for you to try

But what do I know

-

BriCan - Registered Member

- Posts: 2203

- Joined: Wed Apr 07, 2010 12:07 am

- Location: West Coast of Canada

Not by the time I left on the 30th, but possibly since then. I'll be home on the 10th, and will let you know.

Are you planning to finish the cooked ham with a glaze for the client?

Are you planning to finish the cooked ham with a glaze for the client?

-

vagreys - Site Admin

- Posts: 1653

- Joined: Sun Oct 29, 2006 3:54 pm

- Location: North Chesterfield VA USA

BriCan wrote: Phil has his cuz I more or less hand delivered it

...and superb it is too! Many thank Robert.

Forum members will not be aware that you also sent me a large number of commercial recipes. When I'm out of this flamin' bed I'll find some way of getting them online.

Phil

-

wheels - Global Moderator

- Posts: 12894

- Joined: Sat Sep 02, 2006 4:29 pm

- Location: Leicestershire, UK

A thought comes to mind as I savour the ham --- an add from the sixties --- It’s too good to hurry mint

http://www.youtube.com/watch?v=51Oq9CHblPU

http://www.youtube.com/watch?v=51Oq9CHblPU

But what do I know

-

BriCan - Registered Member

- Posts: 2203

- Joined: Wed Apr 07, 2010 12:07 am

- Location: West Coast of Canada

It has been some time since the last update; four hams cooked and passed on to the client so it would seem that they are happy with the outcome as they have not put me on their black list (not sure if they have one or go by the rule of just not phoning you back)

All things aside the ham itself has a great taste ‘but’ to me there seems to be something missing and as Tom and I were going over the cooking process and the outcome the discussions centred on the cooking and spices..

My cooking process had not changed but to me (my taste) I felt that the ham had come out dry(ish) to where I felt that it should be; the cooking process was as always in a pre-heated (gas) oven as I do all my Gammons. In the roasting pan full of liquid on a 300 degree F temperature, cooked to an internal temperature of 140 degrees F when it was taken out of the oven and left on the side for half hour when the temperature was checked again and showed 165 degrees F which is where it had to be to be fully cooked. This process was and is exactly the same as we do for our cooked Gammons which turn out super moist. – These hams were as different as chalk and cheese.

The other concern that I had was that there was no distinction between the spices, yes you could tell the spices but to me there was not the same as the Suffolk where it left you wondering what that hidden spice/flavour hiding behind the array flavours, the consensus was that flavour was muddy and I felt that spices needed to be increased in certain cases.

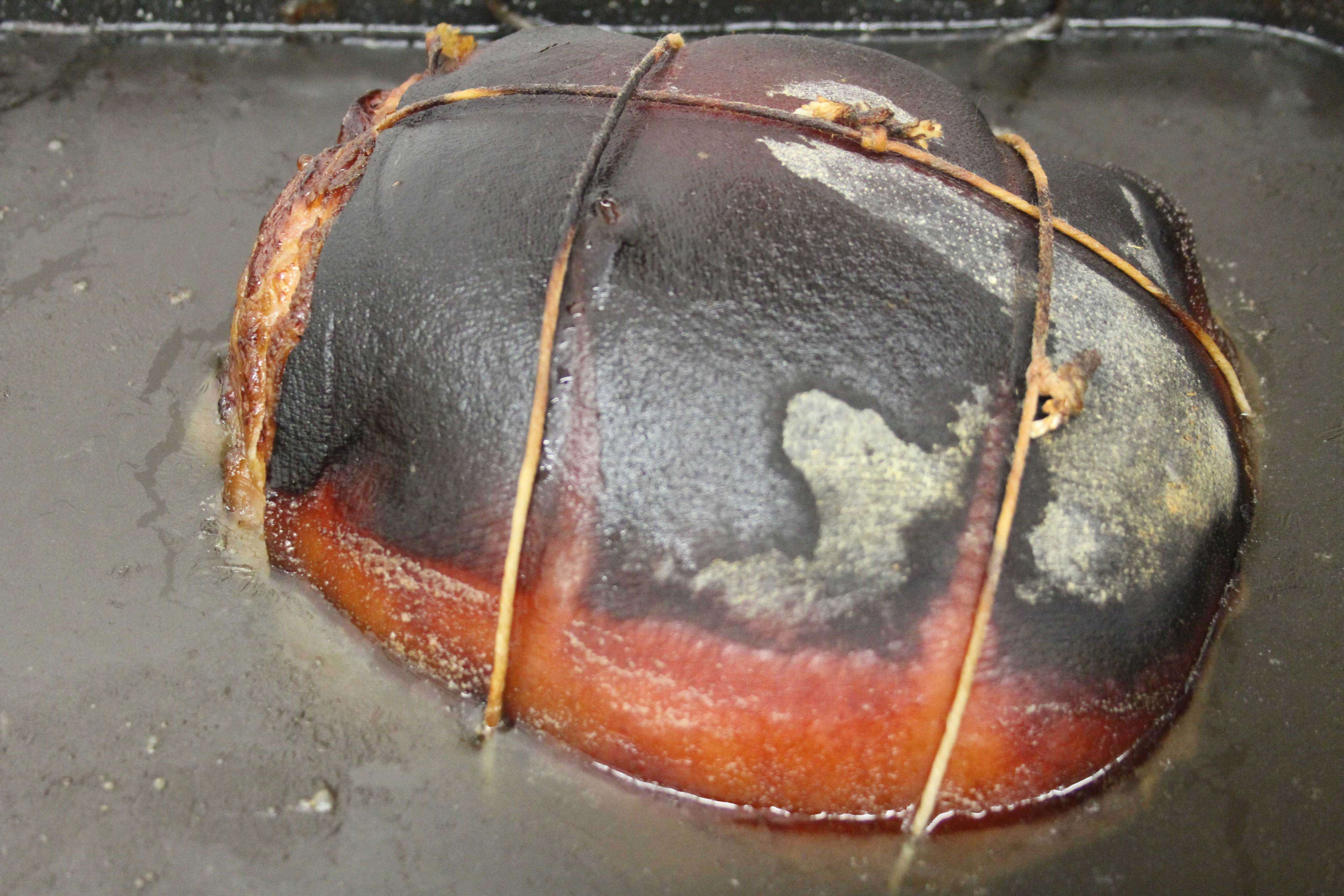

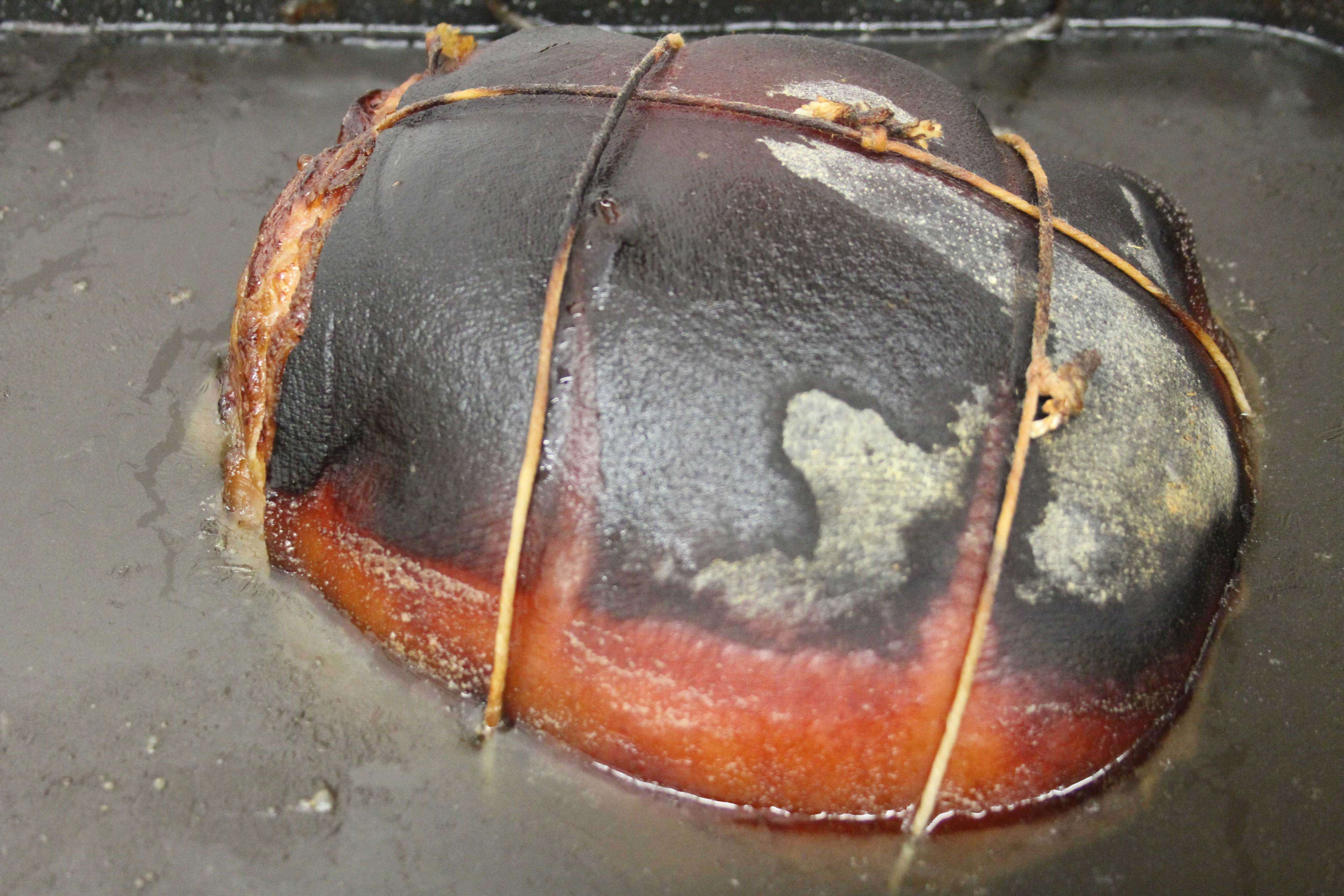

The following is the cooked Irish ham; notice the lower edge showing classic signs of being over cooked and hence being on the dry side on tasting.

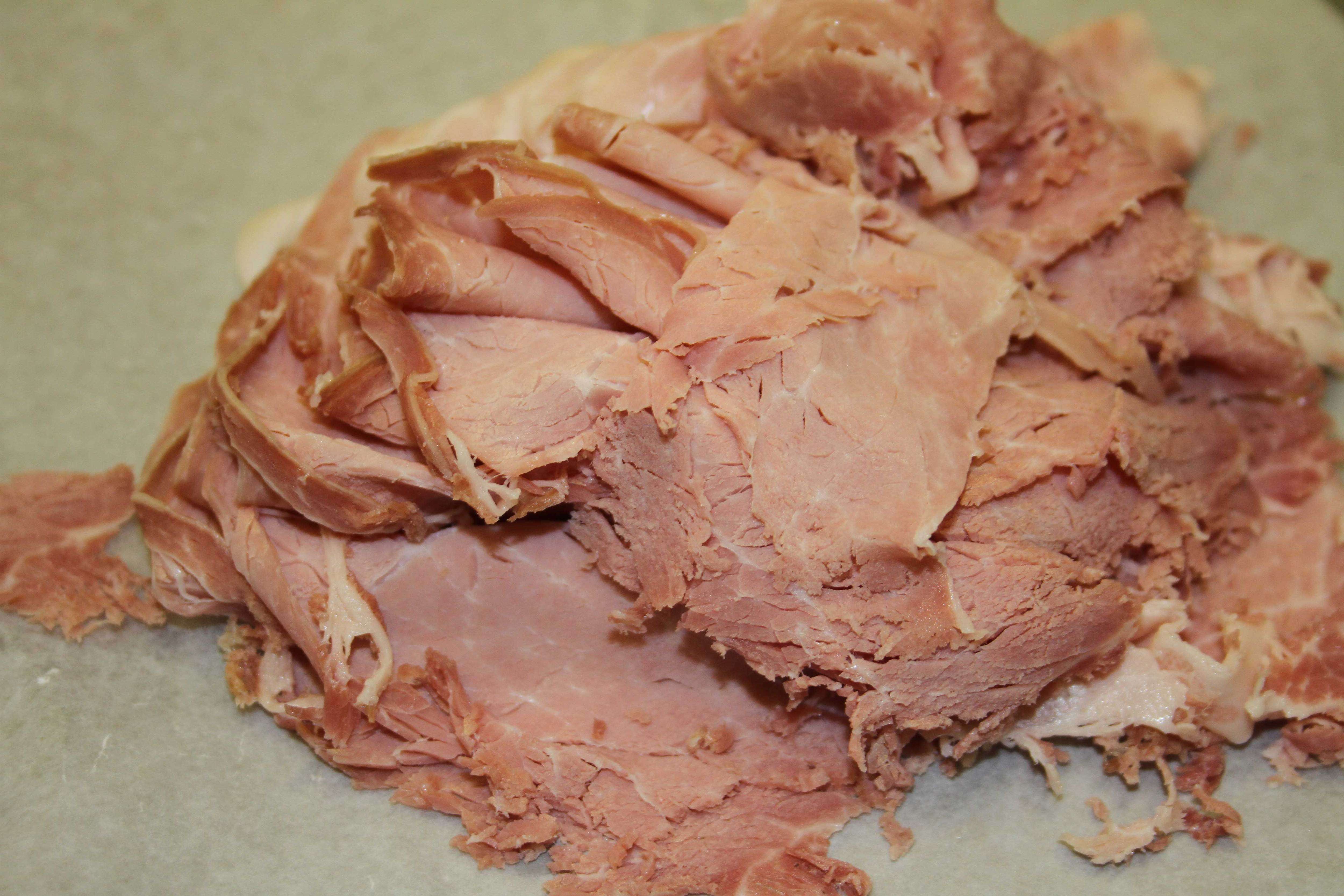

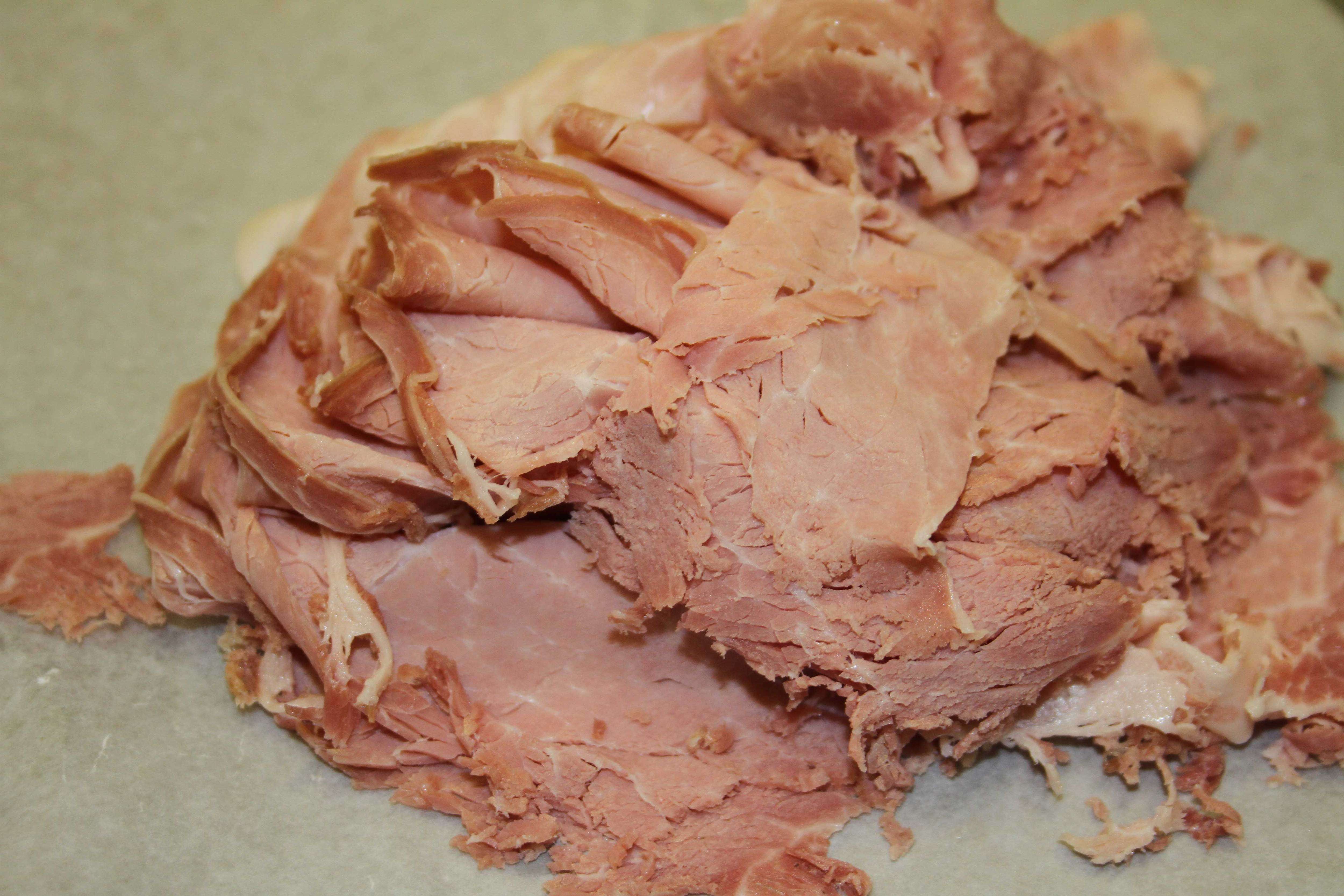

This is the cooked Irish ham sliced

As always we do not toss out the liquid we cook the hams in; we save and recycle (it’s the green thing, or in our case adding flavour on flavour) and use in our pork pies

With that being said it is now on to the next;

the following is Part I of Part II

– more to come

All things aside the ham itself has a great taste ‘but’ to me there seems to be something missing and as Tom and I were going over the cooking process and the outcome the discussions centred on the cooking and spices..

My cooking process had not changed but to me (my taste) I felt that the ham had come out dry(ish) to where I felt that it should be; the cooking process was as always in a pre-heated (gas) oven as I do all my Gammons. In the roasting pan full of liquid on a 300 degree F temperature, cooked to an internal temperature of 140 degrees F when it was taken out of the oven and left on the side for half hour when the temperature was checked again and showed 165 degrees F which is where it had to be to be fully cooked. This process was and is exactly the same as we do for our cooked Gammons which turn out super moist. – These hams were as different as chalk and cheese.

The other concern that I had was that there was no distinction between the spices, yes you could tell the spices but to me there was not the same as the Suffolk where it left you wondering what that hidden spice/flavour hiding behind the array flavours, the consensus was that flavour was muddy and I felt that spices needed to be increased in certain cases.

The following is the cooked Irish ham; notice the lower edge showing classic signs of being over cooked and hence being on the dry side on tasting.

This is the cooked Irish ham sliced

As always we do not toss out the liquid we cook the hams in; we save and recycle (it’s the green thing, or in our case adding flavour on flavour) and use in our pork pies

With that being said it is now on to the next;

the following is Part I of Part II

– more to come

But what do I know

-

BriCan - Registered Member

- Posts: 2203

- Joined: Wed Apr 07, 2010 12:07 am

- Location: West Coast of Canada

Re: Dry Cured Ham ...... Irish Ham

And so the wheels of time move slowly ................

Much water has gone under the bridge along with a ton of sunrises as well as sunsets

I need to revise/look at all things and hopefully bring things back on track so will be stating back at the beginning....

The one thing that I need to do is sort out how the heck will I be able to smoke such a thing, .......... I would/will do the smoking as what was discussed at the onslaught of this project and that was to smoke with peat

The reason why I did not attempt this on the initial smoke was because I did not trust the people at the smokehouse to follow a few simple rules to complete such an undertaking .....

One/friends; will be wondering what the heck am I talking about .... the following is the reason ......

these things happen when people do not clean out the smokehouse, a chore I use to hate but did every two weeks

Much water has gone under the bridge along with a ton of sunrises as well as sunsets

I need to revise/look at all things and hopefully bring things back on track so will be stating back at the beginning....

The one thing that I need to do is sort out how the heck will I be able to smoke such a thing, .......... I would/will do the smoking as what was discussed at the onslaught of this project and that was to smoke with peat

The reason why I did not attempt this on the initial smoke was because I did not trust the people at the smokehouse to follow a few simple rules to complete such an undertaking .....

One/friends; will be wondering what the heck am I talking about .... the following is the reason ......

these things happen when people do not clean out the smokehouse, a chore I use to hate but did every two weeks

But what do I know

-

BriCan - Registered Member

- Posts: 2203

- Joined: Wed Apr 07, 2010 12:07 am

- Location: West Coast of Canada

Re: Dry Cured Ham ...... Irish Ham

The old saying 'There's no smoke without fire' seems to have been taken literally ! Reminds me when I was a kid and everyone had open coal fires burning. The ones that never had their chimneys swept regularly would end up belching out flames four foot high as the build up of soot ignited.

How's the Hams doing - any change in the spice mix/cure ?

How's the Hams doing - any change in the spice mix/cure ?

"Success is going from failure to failure without a loss of enthusiasm." - Sir Winston Churchill

-

yotmon - Registered Member

- Posts: 637

- Joined: Sat Mar 10, 2012 2:07 pm

- Location: North west England

49 posts

• Page 3 of 4 • 1, 2, 3, 4

Who is online

Users browsing this forum: No registered users and 1 guest